Our new coating line allows us to process rebar in a wide range of sizes, from 1/2″ to 2″ in diameter, ensuring the quality and performance our customers expect. You can send us your steel to coat or choose from our extensive inventory for a quick turnaround.

The Benefits of Epoxy Coating

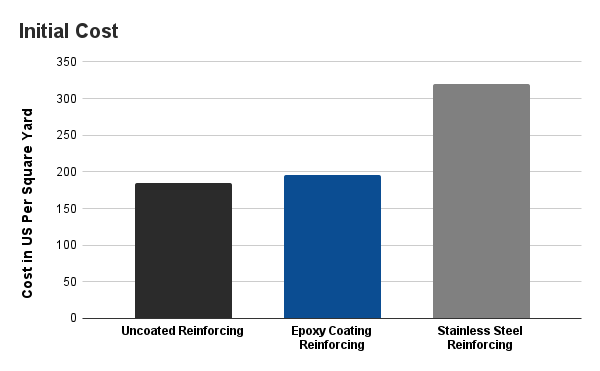

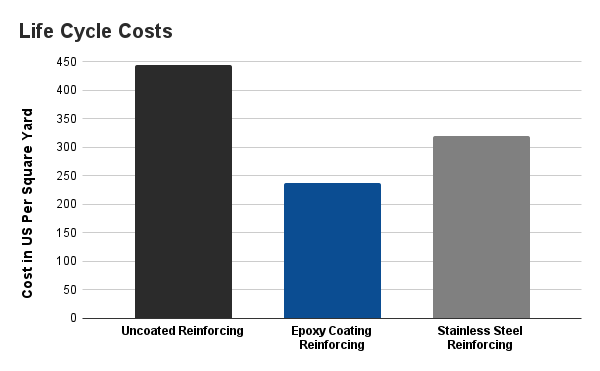

Epoxy coating offers unmatched value in the concrete and construction industries by protecting rebar from corrosion, extending the material’s lifespan, and providing the lowest life cycle cost. This makes it an ideal choice for bridges, parking structures, pavements, marine buildings, and structural repair work. Contractors and builders rely on its commitment to quality for long-lasting results. Here’s a quick comparison of reinforcing options:

Uncoated Reinforcing Steel

The shortest lifespan and highest lifecycle cost.

Epoxy-coated Reinforcing Steel

Reduced corrosion rates and cost-effective over both initial and life cycle costs, making it more economical than uncoated or stainless-steel options.

Stainless Steel Reinforcing

Higher initial costs (about 70% more than uncoated steel) with a life cycle cost about 35% greater than epoxy-coated steel.

Why Epoxy Coating Offers Superior Performance & Value

EAL MFG is certified by the Concrete Reinforcing Steel Institute (CRSI), demonstrating our commitment to meeting the highest quality standards in the concrete and construction industries. Our coating process includes rigorous surface preparation, cleaning, heat and powder application, cooling, and inspection to ensure excellence for contractors and builders.

Quality Control Policies and Procedures:

- Plain bar inspection and testing

- Coating continuity and thickness measurement

- Coating flexibility testing

- Proper handling and storage practices

Our Coating Capabilities:

We can coat:

- Bar lengths from 30’ to 60’

- #4 to #14 deformed bar sizes

- Smooth round bar from ½” to 2” diameter

- Multiple state specifications as required by customers

Standard specs: ASTM A775, A1078, AASHTO M254 (AASHTO M284), ASTM A934

(Straight lengths only over 30’)